The Epoxy 325 is the first step in an epoxy floor coating system. This primer is applied after the concrete has been etched or grind-ed. Before applying an epoxy floor coating it is best to scarify and rough up the surface of the concrete in order for the coating to properly bond and adhere. This can be achieved by acid etching and neutralizing the concrete or by mechanically grinding the concrete with a floor grinder.

Once the surface has been properly prepped the Epoxy 325 can then be applied with an epoxy glide roller. The Epoxy 325 is available in a two component kit. Each kit contains a Part A and a Part B. Part A and Part B are mixed together with a drill or jiffy mixer. Once Part A and Part B are mixed the Epoxy 325 must be applied within 1 hour. About 7-10 hours after applying the Epoxy 325, the Urethane 645 can then be applied as a top coat.

The Epoxy 325 is available in clear or colored. If you are using a colored epoxy primer you are going to want to use the same color top coat. Paint chips (for decoration) or aluminum oxide (for slip resistance) can be cast into the wet epoxy and then top coated with the Urethane 645.

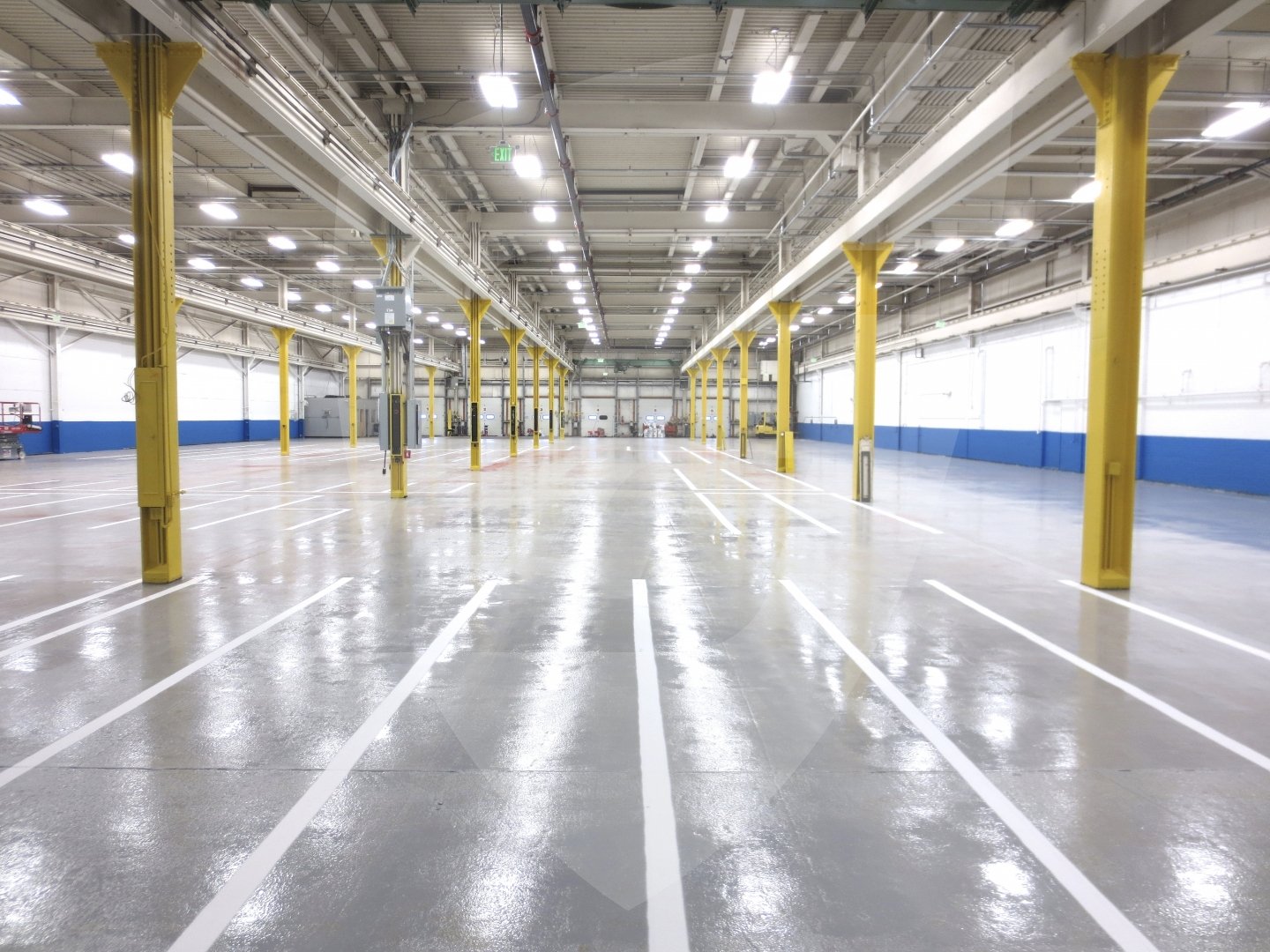

The combination of the Epoxy 325 primer and Urethane 645 top coat are excellent at stopping dusting, repelling oils, greases, chemicals and acids; however, they can only be used on indoor concrete floors.

If there is moisture in the concrete prior to application first use the Vapor-Tek 440.

The Micro-Degreaser 1100 can be used to degrease and remove soils and stains prior to using the Epoxy 325.

The Hydro-Etch 1000 can be used to etch the concrete prior to applying the Epoxy 325.